65'000 Nm or 130'000 Nm Options

7 Tons

1200 mm/20 sec

300 Bar

6000 Nm at 8 RPM

300 Bar (Standard)

500 Bar (With Optional Intensifier)

1200L

800L

Grey and Red

380/415/460V, 50/60 Hz, 3 phase, 15 amp

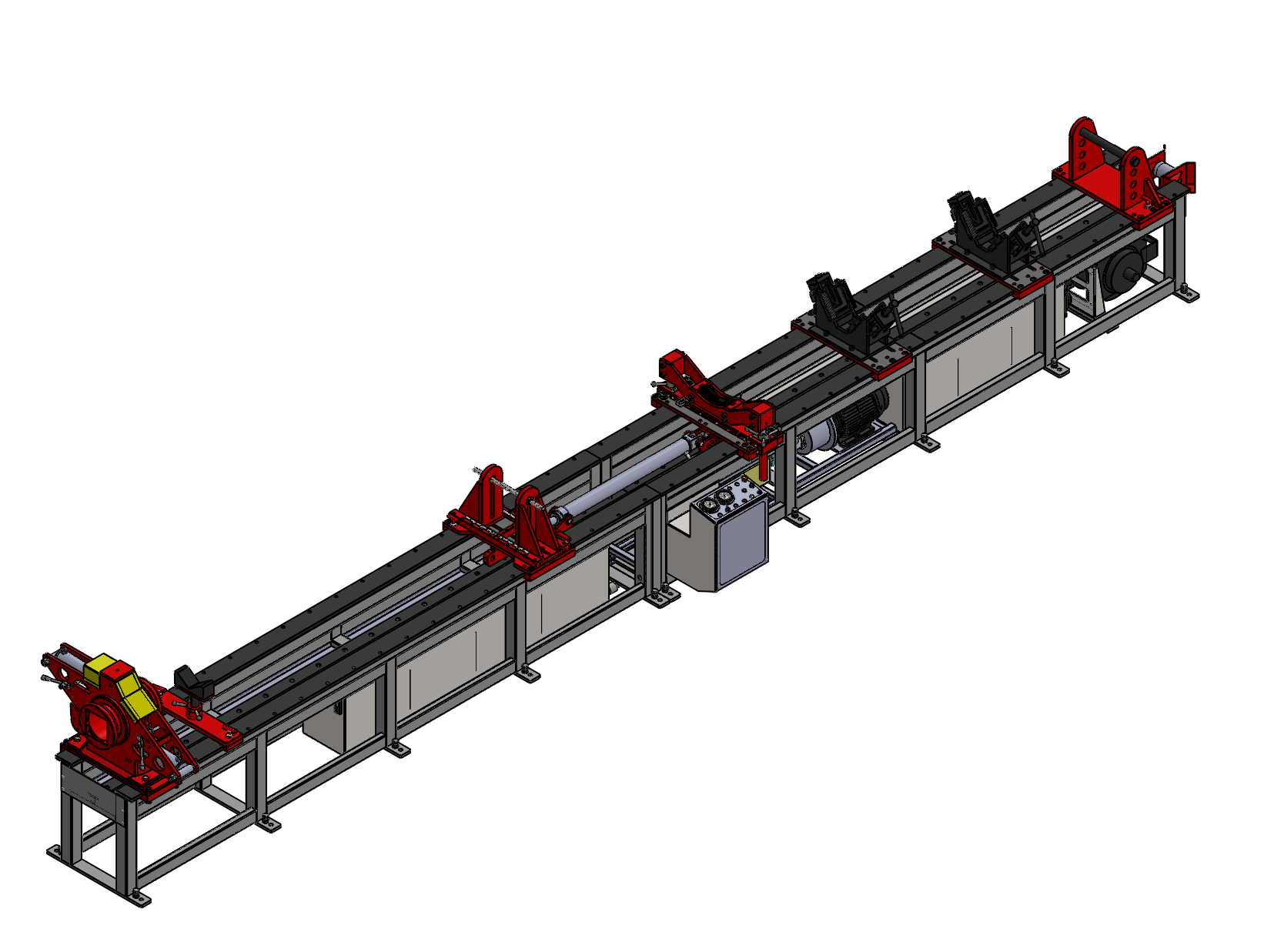

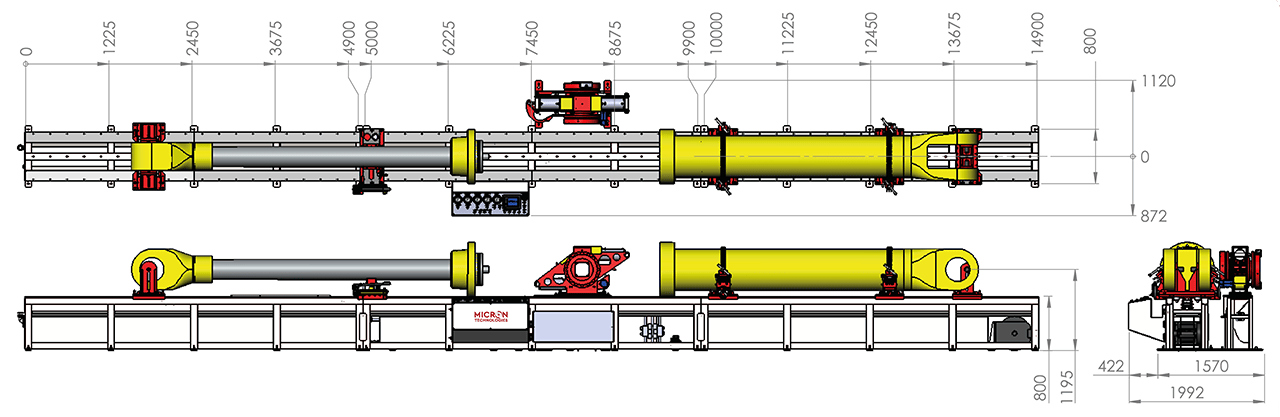

15000mm (L) x 1250mm (w) x 1620mm (h)

Maximum Rotational Torque

Maximum Rod Extraction Force

Max Rod Extraction Speed

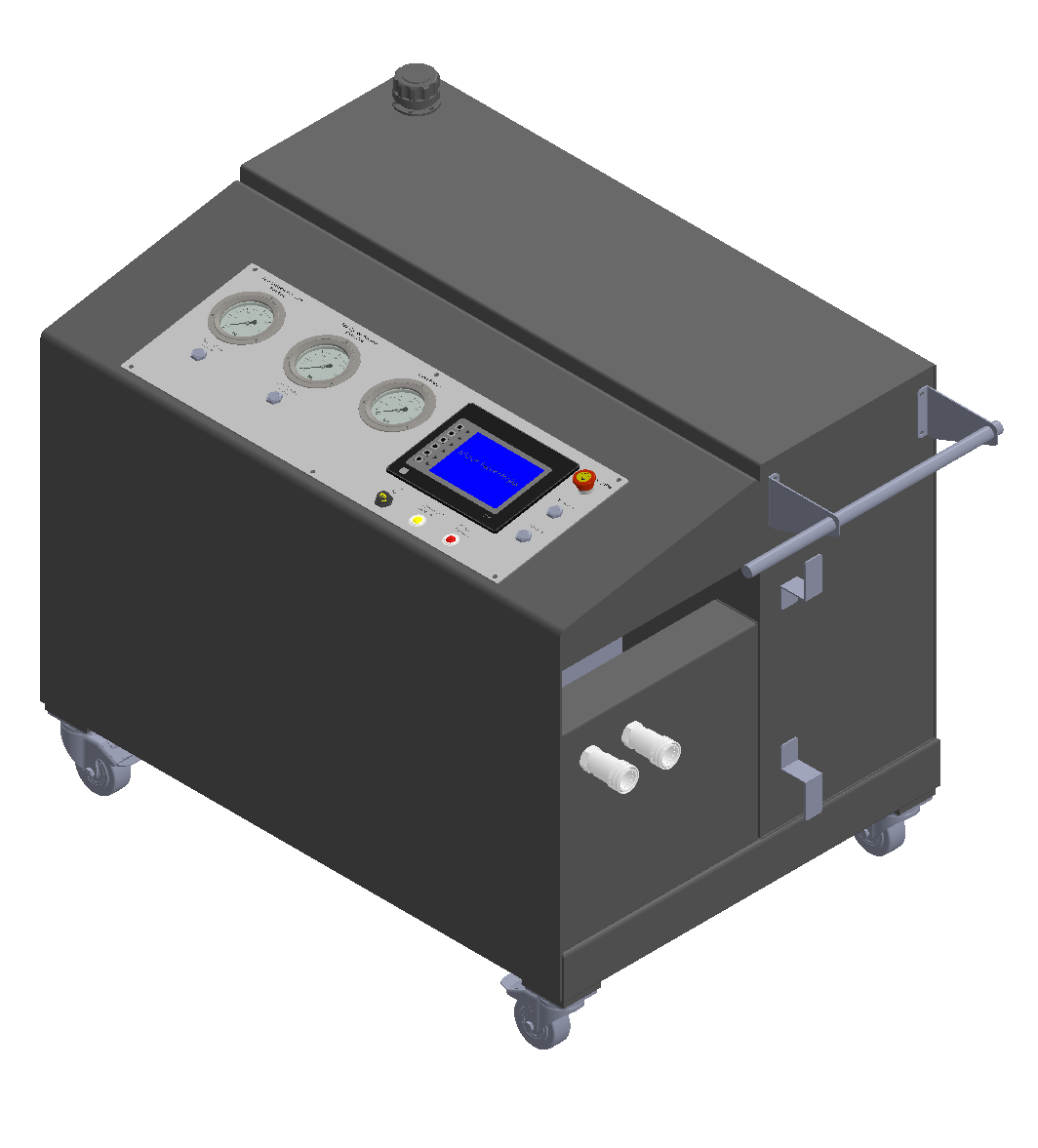

Hydraulic System Pressure

Hydraulic Nut Runner

Cylinder Pressure Test Capacity

Hydraulic Fluid Reservoir

Waste Oil Reservoir

Colour

Electrical System

Floor Space (15-meter bench)

Maximum Part Weight

Maximum Cylinder Length

Maximum Cylinder Barrel

Maximum Cylinder Flange

Maximum Clevis Width

Maximum Clevis Diameter

6000kg / fixture

Not Applicable - Modular Base

620 mm

800 mm

700 mm

620 mm

Please Note:

These are standard specifications.

Special systems can be designed to suit specific requirements.

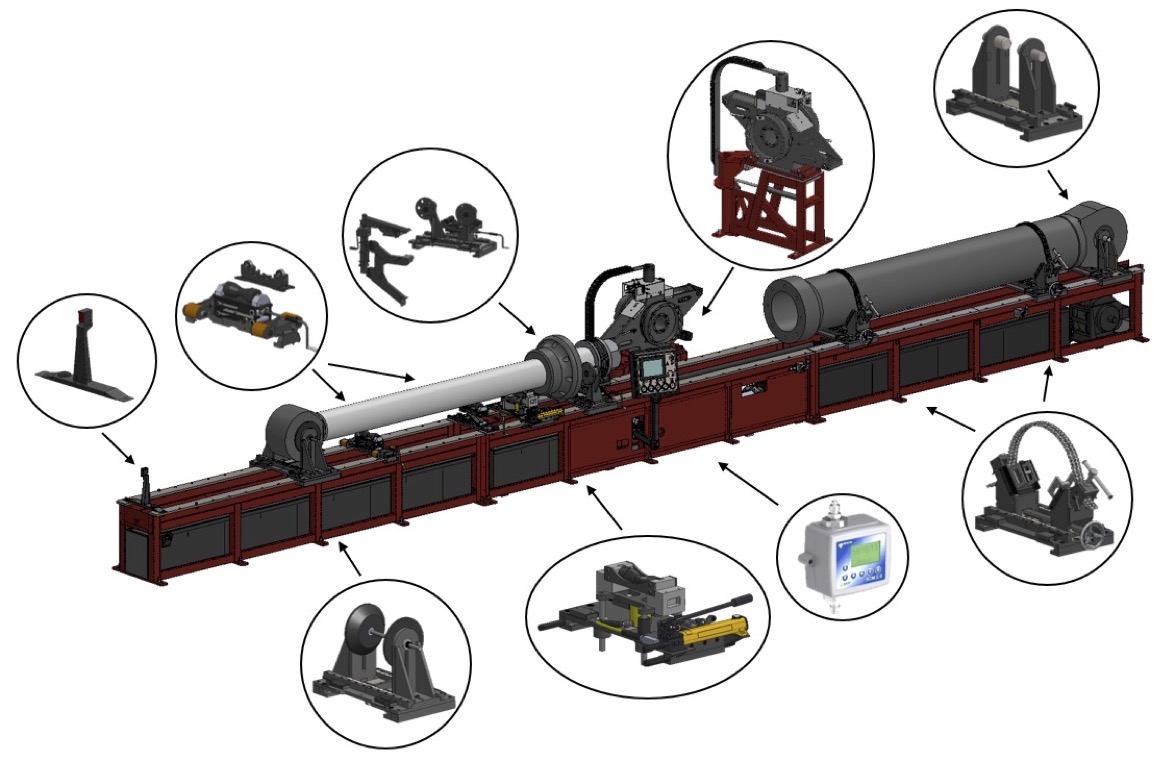

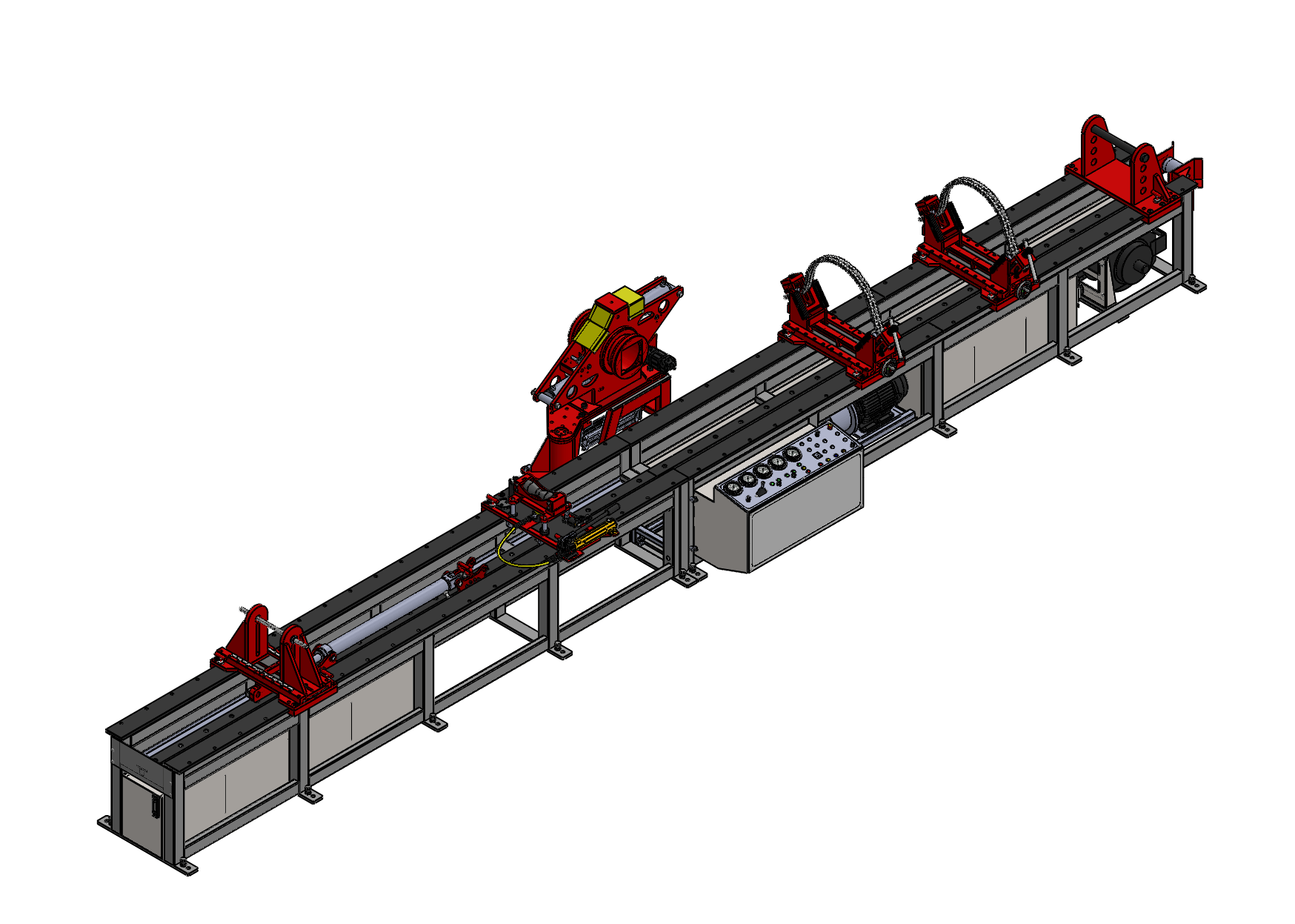

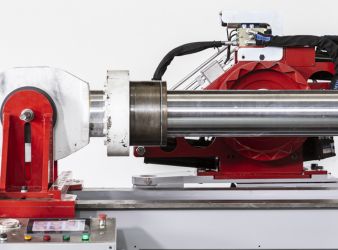

130'000 NM NUT CRACKER &

STRIPPING/ASSEMBLY FUNCTIONS

DIGITAL PRESSURE TESTING

WITH LASER STROKE MEASUREMENT

AND DATA LOGGING TO 300 BAR

(OPTIONAL 500 BAR)

More Info

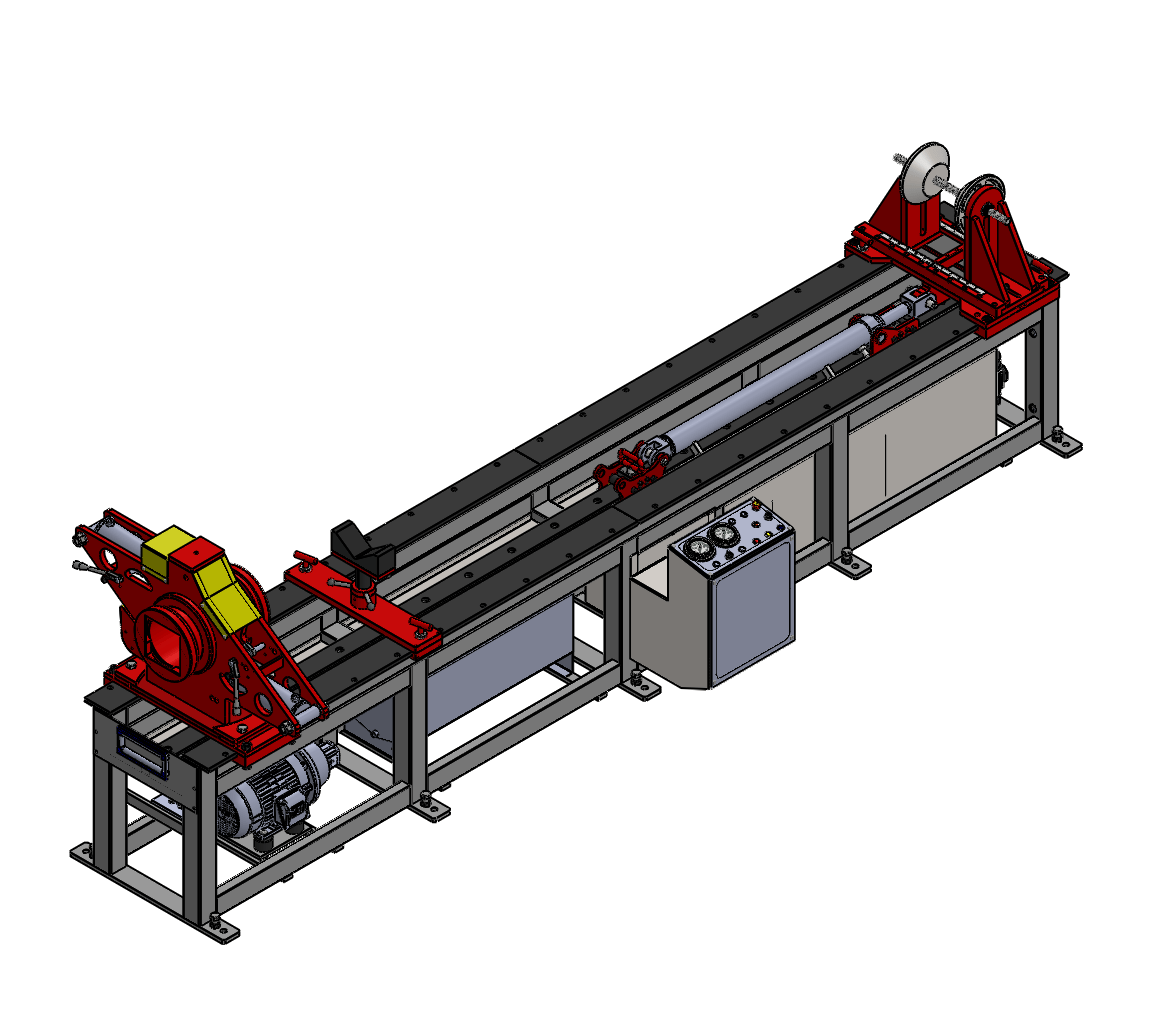

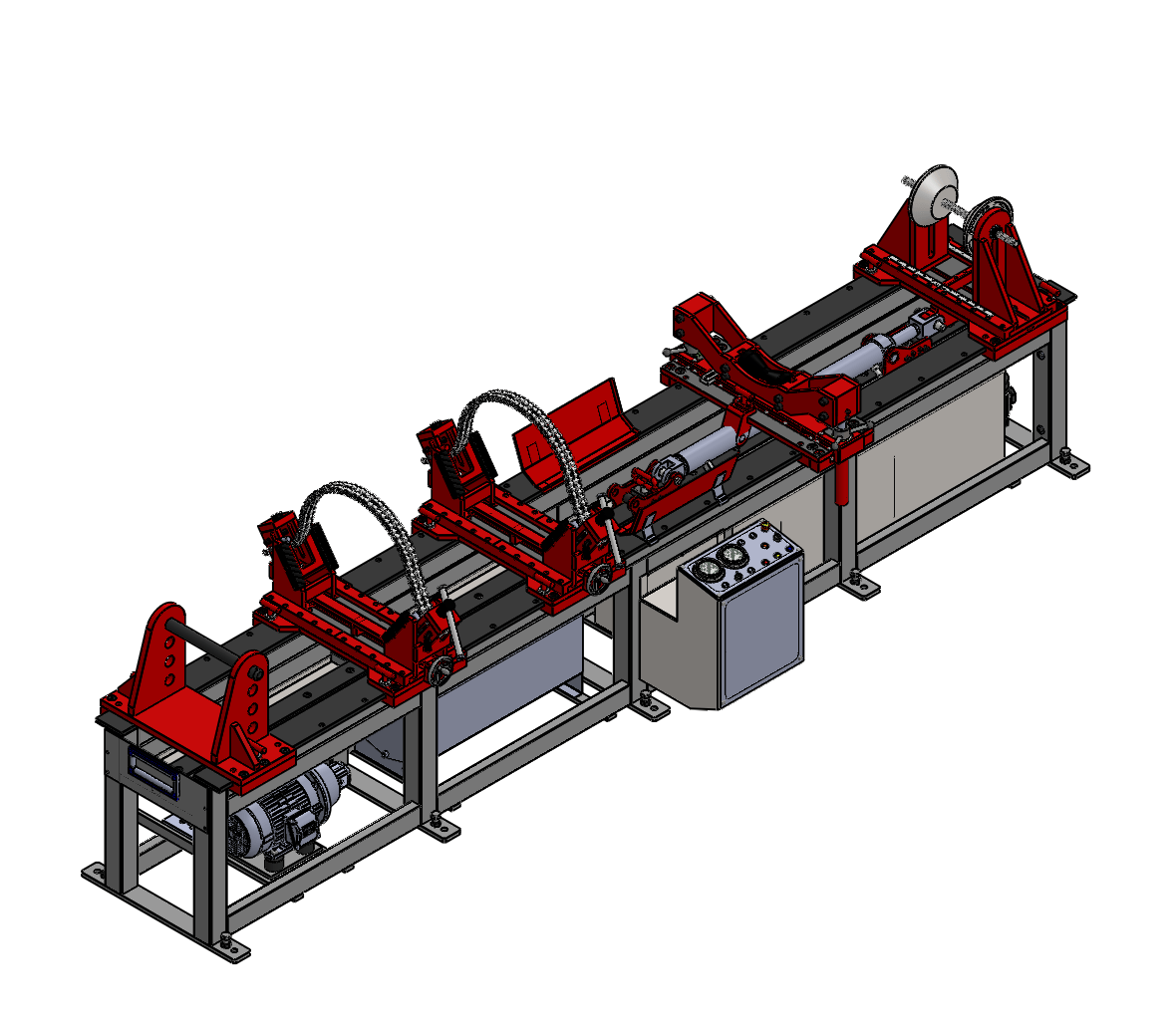

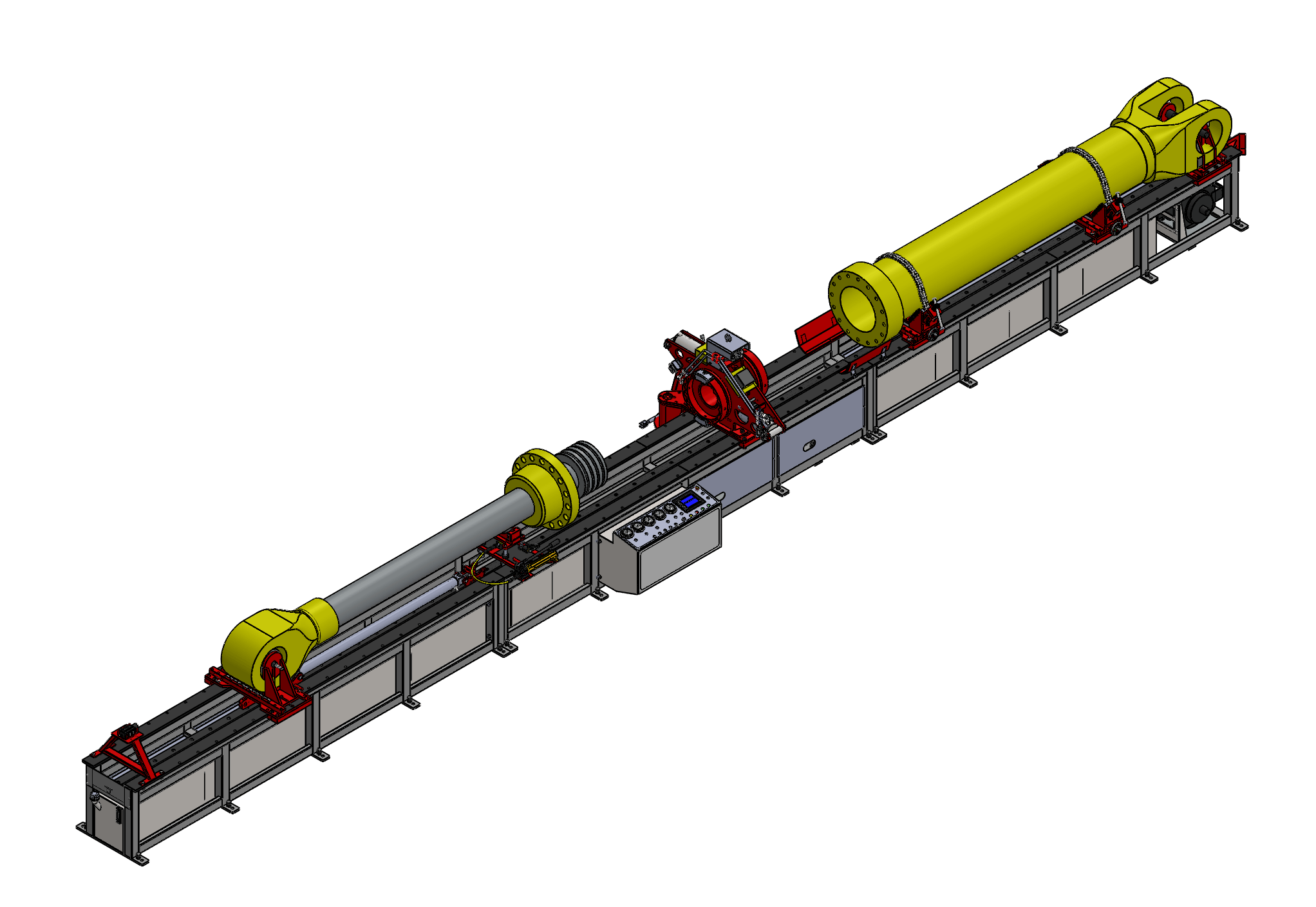

Most important of our benches is that one person can easily disassemble and reassemble cylinders and test them automatically.

Advantages of the Hydraulic Cylinder Repair Bench, Disassembly, Assembly and Test Bench in one to easily repair hydraulic cylinders.

- The machine has CE and is built under CE and with multi-language control (even your language )

- Our benches are fast, clean, easy to use and very safe

- One person can easily disassemble and reassemble cylinders, even for really large cylinders in under 1 hr

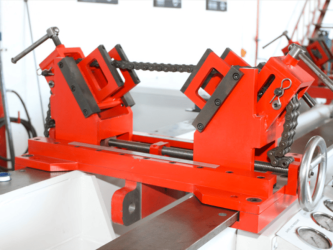

- Fully Functional Wireless Remote Control to operate the machine, useful when moving the piston with seals back into the cylinder

- No dangerous protruding parts

- No obstacles on the floor, such as rails or hoses

- Everything at one common centre height

- All the tools on the bench are on rollers and can move very easily

- Maximum weight per fixture - 6000 kg (2 = 12000 kg and 3 = 18000 kg)

- Diameter Indication to set or adjust the tool for the correct cylinder diameter

- Hydraulic Oil System Reservoir with filtration for the system and to test the cylinders (up till the requirement)

- Waste Oil Reservoir with full-length oil collector tray over the entire machine length, and you can pump this with the integrated dirty oil pump off into your loop system (big waste oil tank)

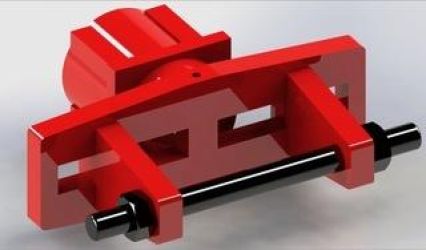

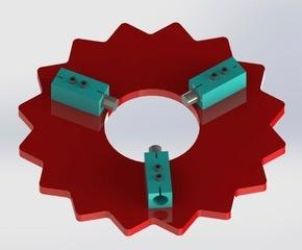

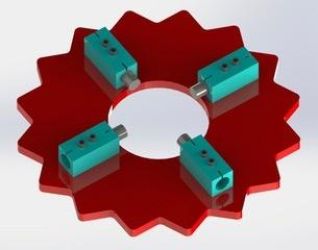

- Special tooling for different glands with pins or slots and ball claps to hold these to unscrew the piston nut

- Everything is compact on or under the bench

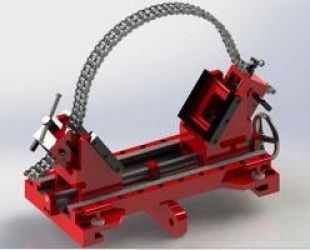

- Nut Cracker has a Swing Table to remove Nut Cracker from Bench or to the bench where you can rotate it 180 degrees to change the rotation for clock or counterclockwise (open or close)

- The rotation of the nutcracker is continuous, and you do not need to insert any pins to continue the process, the 2 cylinders ensure that the nut is turned from the center and gives a force of 135,000 Newton meters

- The nutcracker can rotate the nut continuously at a lower torque and at a higher rotation speed

- Standard Tooling up to hex size 345mm

- Online support and monitoring with remote connectivity via LAN, WiFi, GSM for fast tech support. If there is an issue we can normally identify the problem and either reset, adjust or advise and can help resolving the fault.

- SCADA Operator Interface

o Web-enabled

o Digital Torque Pre-sets and Logging

o Digital Pressure Testing and reporting

o Industry 4.0 Ready

o Read out the used torque needed to open the nut

o Laser Stroke Measurement (measure and store the stroke length)

o Automated ‘multi-point’ pressure testing

o Measure if there is a drift of the piston and store this and more in the report

o Digital Test Report

o Up to 500Bar

- After testing, you can press the test oil out of the cylinder to deliver it empty

- Customisable test report

- High-quality components such as Moog Electronic

There are 4 types:

o Lean Design - 30’000Nm. Torque Max. Suitable for standard and smaller sized cylinders whit a max length of 2500mm (Closed Centres)

o Standard Duty – 65’000Nm. Torque. Suitable for Construction and medium-sized mining cylinders. Max Barrel OD 450mm.

o Heavy Duty – 135’000Nm. Torque. Large Mining and Off-shore cylinders (up to EX8000 Boom Cylinders, wave compensation, etc) Max barrel OD 650mm.

o Ultra Duty - 135’000Nm. Extra Large Mining and/or offshore cylinder (Barrel OD up to 850mm, length 25m +) Optional 200'000Nm. nut cracker