SR SERIES Electric Wrench

Advanced Electronic Control Combined With Industrial Reliability

SR SERIES Electric Wrench

The most precise way to control and track torque

- Total electronic control of torque and angle fastening

- Touch sense operation and document filing

- Durable industrial materials and construction

Advanced Electronic Control Combined With Industrial Reliability

The SR Series is more than an electric powered wrench, it is an electronic torque controlled documentation system.

The TorcUP STRYK provides the most advanced tightening strategies for critical applications that require documented tight tolerance accuracy.

PROVIDES THE MOST ADVANCED TIGHTENING STRATEGIES

- Made In USA

- Five Models From 100 Ft/Lbs to 6,000 Ft/Lbs - 136 Nm. to 8135 Nm.

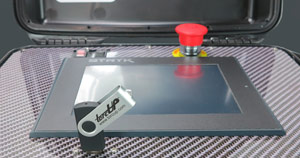

- Touchscreen Graphical Display / 640 x 480 Pixels

- Memory Total 512KB / USB Port (Data & Updates)

- Input Voltage 100-240VAC – 50/60 H

Through the use of integrated encoders both torque and torque plus angle control are available at the touch of the screen. Angle control is available in both tighten and loosen directions for a total solution to your engineered specifications. Utilizing the same gear train design as our legendary RP Series, the STRYK outperforms all other methods in long term reliability as well as mechanical repeatability. Simply put, THIS IS THE MOST DURABLE ELECTRONIC TORQUE WRENCH SERIES EVER PRODUCED!

Specifications

| Model Number | SR-500 | SR-1000 | SR-2000 | SR-3000 | SR-6000 |

|---|---|---|---|---|---|

| Square Drive | 3/4" | 1" | 1" | 1" | 1 1/2" |

| Min Torque (ft/lbs) | 100 | 200 | 400 | 600 | 1200 |

| Max Torque (ft/lbs) | 500 | 1000 | 2000 | 3000 | 6000 |

| Min Torque (nm) | 136 | 271 | 542 | 813 | 1627 |

| Max Torque (nm) | 678 | 1356 | 2712 | 4067 | 8135 |

| Output Accuracy at set torque | +/- 3% | +/- 3% | +/- 3% | +/- 3% | +/- 3% |

| Repeatability | 100% | 100% | 100% | 100% | 100% |

| Duty Cycle | 100% | 100% | 100% | 100% | 100% |

| Tool Weight w/o reaction arm | 10.9lbs / 4.9kg | 14lbs / 6.4kg | 15.6lbs / 7.1kg | 22.3lbs / 10.1kg | 38.3lbs / 17.4kg |

| Standard Reaction Arm | 2.05lbs / 0.93kg | 2.85lbs / 1.29kg | 2.85lbs / 1.29kg | 2.85lbs / 1.29kg | 7.85lbs / 3.56kg |

| RPM @ min torque | 2.6 | 2 | 3 | 1.4 | 1.9 |

| RPM @ max torque | 25.8 | 10 | 6 | 2.8 | 1.9 |

| Control Box | 20lbs / 9.07kg | ||||

| Power Cable | 1.65lbs / 1.65kg | ||||

| Data Cable | 3.85lbs / 1.75kg |

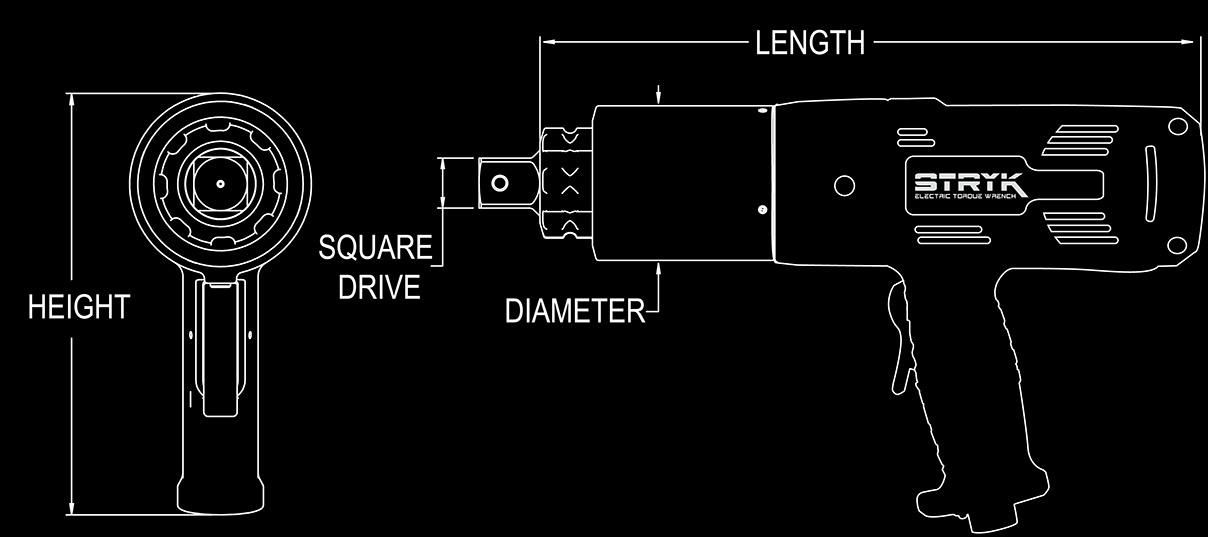

Dimensions

| Model Number | SR-500 | SR-1000 | SR-2000 | SR-3000 | SR-6000 |

|---|---|---|---|---|---|

| Height | 9.29" / 236.0mm | 9.29" / 236.0mm | 9.29" / 236.0mm | 9.31" / 236.5mm | 9.94" / 252.5mm |

| Square Drive | 0.75" | 1" | 1" | 1" | 1.5" |

| Length | 11.45" / 290.8mm | 13.23" / 336.0mm | 13.94" / 354.1mm | 16.18" / 411.0mm | 16.88" / 428.8mm |

| Diameter | 2.56" / 65.0mm | 2.85" / 72.4mm | 3.09" / 78.5mm | 3.75" / 95.3mm | 5.00" / 127.0mm |

Features

USB Port

Touch Screen Control

Single Cord Operation

Sturdy Square Drive

Electric Motor

Cast Reaction Arm

Internal Gear Drive

Ergonomic Handle Design

Dual Operation Trigger

Accessories

Long Reaction Arm

Sliding Reaction Arm

Straight Reaction Arm

Weld Blank

Nose Extension