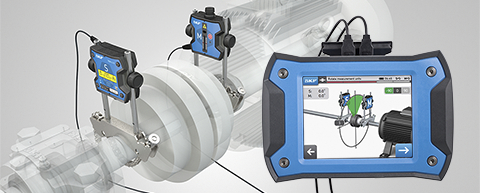

Shaft alignment tool TKSA 31

The intuitive and affordable laser shaft alignment system

The TKSA 31 is SKF’s most affordable solution for easy laser shaft alignment. The ergonomic display unit with touch screen makes the instrument very easy to use and the built-in machine library helps storing alignment reports for multiple machines. Large sized laser detectors in the measuring heads reduce the need for pre-alignments and the embedded soft foot tool helps establish the foundation for a successful alignment.

Additional functions such as live view and automatic measurement support fast and effective alignment tasks and make the TKSA 31 an innovative laser shaft alignment tool that is affordable for almost every budget.

Shaft alignment is recommended for almost every industry, as it helps to increase machine uptime, decrease production losses and reduce maintenance costs. The TKSA 31 is the ideal solution for entry-level laser shaft alignment. Its intuitive usage helps to achieve accurate alignments while the TKSA 31 remains affordable for almost every budget.

Features and Benefits

- Easy measurements can be performed by using the well-known three position measurement (9-12-3 o’clock) with additional positioning flexibility of 40° around each measurement position.

- High affordability is achieved by focussing on the standard shaft alignment process and essential functions to allow quick and effective shaft alignments.

- "Automatic measurement” enables hands-free measurements by detecting the position of the heads and only taking a measurement when the heads are in the right position.

- Automatic reports are generated after each alignment and can be customised with notes about the application. All reports can be exported as pdf files.

- Live view supports intuitive measurements and facilitates horizontal and vertical machine position corrections.

- The machine library gives an overview of all machines and alignment reports. It simplifies the machine identification and improves the alignment workflow.

Technical Data

Sensors and communication

29 mm (1.1 in.) CCD with line laser; electronic inclinometer ±0,5°; Bluetooth 4.0 LE or USB cables (included)

Wired communication

with USB cables (included)

System Measuring distance

0,07 to 2 m (0.23 to 6.6 ft.)

Measuring errors / displayed resolution

<0,5% ±5 µm / 10 um (0.4 mils)

Display type

5.6" colour resistive touchscreen LCD

Software update

via USB stick

Shaft diameters

20 to 150 mm (0.8 to 5.9 in.) diameter Up to 300 mm (11.8 in.) with optional extension chains

Max. recommended coupling height **

105 mm (4.2 in.) Mounting system 2 × V-brackets; 2 × chains 400 mm (15.8 in.); 2 × threaded rods 150 mm (5.9 in.) per V-bracket

Alignment measurement

3 position measurement 9–12–3 3 position automatic measurement 9–12–3

Alignment correction

Live values for vertical and horizontal machine position correction; Laser soft foot tool

Alignment report

Automatic pdf report exportable via USB stick

Display unit battery

Up to 7 hours continuous use at 100% backlight (5 000 mAh rechargeable LiPo battery)

Measuring unit battery

up to 12 hours continuous use (2 000 mAh rechargeable LiPo battery)

Carrying case dimensions

530 × 110 × 360 mm (20.9 × 4.3 × 14.2 in.)

Total weight (incl. case)

4,75 kg (10.5 lb)

Operating temperature

0 to 45 °C (32 to 113 °F) IP rating IP54

Calibration certificate

Supplied with 2 years validity

* With standard USB cables supplied, up to 4 m (13.1 ft.) possible

** Up to 195 mm (7.7 in.) with extension rods (optional)